Wood has long been a fundamental material in building and design. Today, it also stands out as one of the most sustainable and renewable natural resources available. In North America responsible forest management has produced a remarkable outcome: forest growth has exceeded harvest levels for more than 50 consecutive years, meaning there are more trees in our forests today than in decades past thanks to careful stewardship and regeneration efforts. Our forests act as major carbon sinks by capturing carbon dioxide from the atmosphere and storing it in wood products used every day. Southern Pine forests in particular, are among the most productive and sustainable timberlands in the world, and the lumber and wood products they produce contribute greatly to the long-term storage of CO2.

Harvesting trees under sustainable forestry practices is not about depletion, it is about renewal. Forest managers balance harvests with planned regeneration and natural seeding to ensure that forests remain vibrant, diverse, and productive. This approach also supports carbon storage long after trees leave the forest. When wood becomes lumber, furniture, or other durable products, much of the carbon absorbed by the tree remains locked in place through the life of that product, keeping it out of the atmosphere and contributing to climate mitigation goals.

Extending Life Through Treatment and Standards

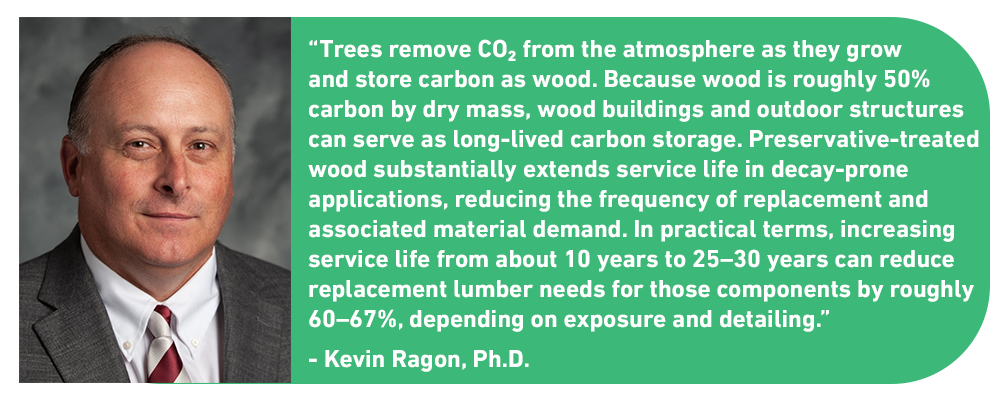

As Dr. Kevin Ragon of Mississippi State University explains, “Trees naturally clean greenhouse gasses, especially CO2, which is why preservative treated wood is a responsible choice as a building material. Scientific research shows treated wood can last eight to ten times longer than untreated wood. That extended service life means roughly a little over six billion board feet of wood are saved each year, enough for approximately 400,000 houses, and results in more than 226 million trees saved annually.”

Sustainability is about longevity as well as renewal. As Dr. Ragon notes, “trees remove CO₂ from the atmosphere as they grow and store carbon as wood, and because wood is roughly 50 percent carbon by dry mass, wood buildings and outdoor structures can serve as long-lived carbon storage. Preservative treatment enhances this benefit by substantially extending service life in decay-prone applications, reducing the frequency of replacement and associated material demand. In practical terms, increasing service life from roughly 10 years to 25 to 30 years can reduce replacement lumber needs for those components by approximately 60 to 67 percent, depending on exposure conditions and detailing”.

Preservative treatment protects wood from decay, insects, and moisture, meaning treated wood products last longer and need less frequent replacement, which contributes to lower overall resource use and reduced waste over time. “Best practices begin with selecting properly seasoned wood, keeping wood dry in service, and avoiding direct contact with soil whenever possible” says Dr. Ragon. When wood cannot be kept dry or isolated from soil, properly treated wood should always be used. The American Wood Protection Association (AWPA) develops consensus-based, ANSI-accredited standards for wood preservatives and treated wood products that are widely recognized and specified across the construction and utility industries. The primary standard for treated wood products is AWPA Standard U1, which provides general specifications for preservatives and the retention levels appropriate for different end-use applications. Properly treated wood can be identified by an end tag on lumber, timber, or round stock that includes the AWPA logo, helping builders and specifiers confirm the product is suited for its intended service conditions. The AWPA Use Category System in Standard U1 further helps match treated wood to expected exposure conditions, enhancing performance and extending service life.

Wood also compares favorably to many alternative materials when it comes to energy and emissions. Producing wood products requires significantly less energy than materials like steel, concrete, or plastic. Life-cycle analyses show that wood from standing timber can require only a fraction of the energy used to manufacture metals or synthetics, supporting lower greenhouse gas emissions over the life of a building or product.

Forest stewardship is a story of progress as well as preservation. By choosing wood from responsibly managed forests, builders and consumers support continued investment in forest health, climate resilience, and renewable material cycles. Across the United States and Canada, sustained forest management has supported strong forest carbon sinks while maintaining a reliable long-term wood supply without compromising ecological health. Continuing this progress depends on educating and inspiring the next generation of professionals in forestry and wood science. Programs like Mississippi State University’s wood products outreach and education efforts play an important role in introducing students to the science, sustainability, and career opportunities within the forest products industry, helping ensure the field continues to grow and innovate.

Sources:

- https://northamericanforestfoundation.org/tree-wood-facts/

- https://northamericanforestfoundation.org/how-much-energy/

- https://www.southernpine.com/why-southern-pine/sustainability/

- https://www.rff.org/publications/explainers/federal-climate-policy-107-land-use-forestry-agriculture/

- https://awpa.com/info/publications/standards

- https://extension.msstate.edu/sites/default/files/document/2025-10/M2483_web_2.pdf